rinorema basa turntable mabhengi pamwe External giya kuuraya mhete

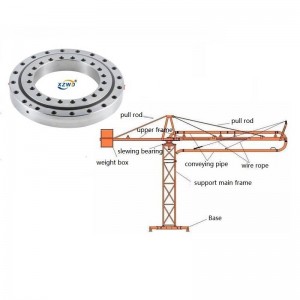

Iko kubata uye kukotama simba regiya pasi pekupedzisira uye kuneta mitoro yakaverengerwa uye yakasimbiswa zvinoenderana ne ISO6336-1: 2006, ISO6336-2: 2006 uye ISO6336-3: 2006 zvakateerana.Sf ndeye 1.48 uye iyo giya mesh clearance inogadziriswa kune yepamusoro poindi yeradial inobuda kunze.kuurayagear pitch circle.Iko kucheneswa kwemazino kunowanzo kuve 0.03 kusvika 0.04x modulus, uye iyo giya mesh kucheneswa kwepinion giya pane yese denderedzwa inoda kutariswa zvakare mushure mekusungirirwa kwekupedzisira kweiyo.kuuraya.

Single-mutsara mana-point kuonana bhora kurovera mhete yemukati bhora machining kurongeka uye yemukati nhangemutange machining kurongeka hakuna kukwirira, kana pane hurema hwemhando uye kushomeka kwemafuta ekuzora mujaho remujaho uye kudhumhana kwe spacer, zvinokanganisa zvakananga kushanda kwakatsetseka kwemhete inouraya. uye ruzha, saka kana uchitarisa kukanganisa mhete yekuuraya, dzimwe nguva nekutsiva bhora kuderedza kuwanda kwekutadza.

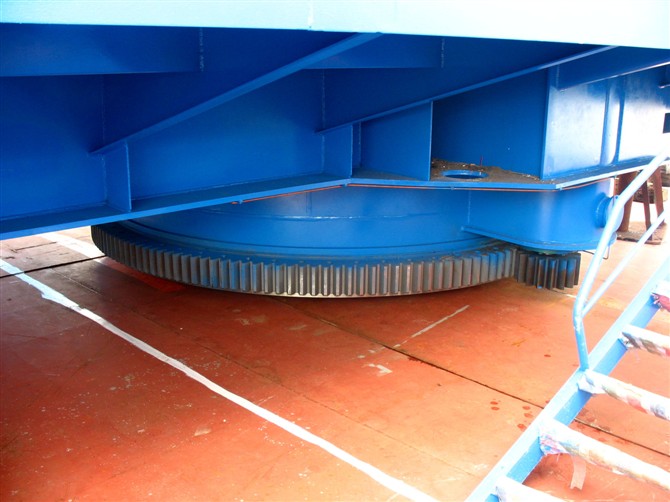

Nekuda kwegiya riri pasi pemutoro mushure menguva refu yekushanda, pachave nechidimbu chesimbi kana tambo yesimbi padhuze nepitch line, pitting kana gnawing metal chips kure, kuumbwa kwegomba kana mazino.Iyo inouraya inotakura zino pamusoro pepitting nekuwedzera kwenguva yekushanda uye kuwedzera kuitira kuti iyo inouraya inotakura mesh kukuvara kwezino, tower crane inotenderera ruzha uye kukanganisa kunowedzera, kutenderera kwekukanganisa pasi pasi pesimbi zvimedu uye nekumhanyisa kupfeka kweinouraya mhete yemazino pamusoro, kugadzira kutenderera kwakashata.Pamusoro pezvo, kugadzirwa uye kuungana kweiyo mota yekutangisa mune yemhete yemhete ine hurema hwayo kugadzira jitter inokonzeresa, uye maitiro ekubatanidzwa kwevhiri redhiraivha ane kutakura kutakura haana kugadzikana, izvo zvinowedzerawo kuwanda kwejitter uye ruzha rwekudzokorodza. decibels.

Kana iyo weld mhando isiri kusvika pachiyero, iyo weld defect inoda kugadzirwazve uye kugadzirwazve.Mukugadzirisa welding kugadzirisa hakungoburitse kushushikana kutsva kwewelding uye kupfava kweiyo machined mounting surface kuchavawo nekukanganisa kukuru, panguva imwe chete iyo welding ikozvino inogadzirwa mukutakura kutakura kuburikidza nemukati inotenderedza muviri uye kurira mhete yemujaho ichaitawo. kukonzera kumwe kukuvadza.Pamusoro pezvo, zvikanganiso zvegungano mukugadzira gungano, kuisirwa kwemunda kwepini yekuruka uye bhaudhi preload inogonawo kuburitsa ruzha rusina kujairika kana kutaura kana zvinodiwa zvikasaitwa.

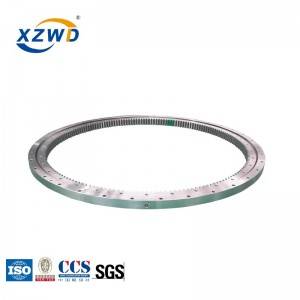

mhete huru yemhando ndeyekunze uye yemukati mhando, iyo hombe uye diki magiya mesh zvisina kunaka, dzimwe nguva yakasimba, dzimwe nguva yakasununguka, mune inouraya mhete zino rinobuda rakanyanya chinzvimbo meshing yakanyanya kusimba inoburitsa ruzha.Saka nzira yekugadzira yakakosha.Slewing bearing ichangosiya fekitori iri idling inoburitsa simbi inotenderedza yunifomu ruzha, izvo zvakajairika.Senge muyunifomu yakajairika kurira kunoperekedzwa neimwe kurira kwakakura zvisingaite hakuna kunaka.Pane zvikonzero zvakawanda zvekukundikana.

1. Yedu yekugadzira mwero inoenderana nemichina yakajairwa JB/T2300-2011, isu takawanikwawo inoshanda Quality Management Systems(QMS) ye ISO 9001:2015 uye GB/T19001-2008.

2. Isu tinozvipira kune R & D yeakagadziridzwa slewing bearing nehupamhi hwepamusoro, chinangwa chakakosha uye zvinodiwa.

3. Nehuwandu hwezvigadzirwa zvekugadzira uye kubudirira kwekugadzirwa kwepamusoro, kambani inogona kupa zvigadzirwa kune vatengi nekukurumidza sezvinobvira uye kupfupisa nguva yekuti vatengi vamirire zvigadzirwa.

4. Unhu hwedu hwemukati hutongi hunosanganisira kuongorora kwekutanga, kuongorora pamwe chete, mu-process quality control uye sampling kuongorora kuti tive nechokwadi chehutano hwechigadzirwa.Iyo kambani ine yakazara yekuyedza michina uye yemhando yepamusoro nzira yekuyedza.

5. Yakasimba mushure mekutengesa sevhisi timu, panguva yakakodzera kugadzirisa matambudziko evatengi, kupa vatengi masevhisi akasiyana.